AKKD Solid Fuel Fan Three Transitive Heating Boilers - General Features

- They have a full automatic burning control system.

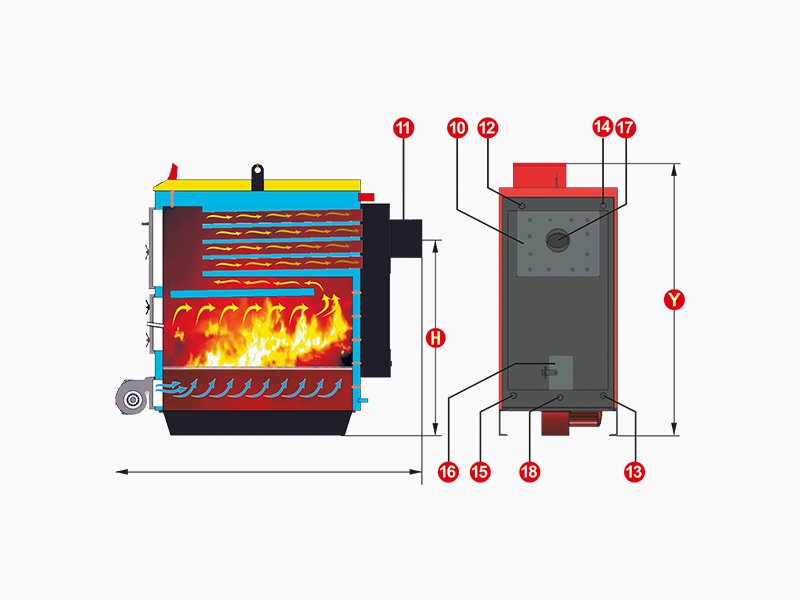

- With fi re tube, Bafi l technology and connected special design, easier removal of smoke gases, decreasing of cinder amount and equal heat transfer in all surfaces within the boiler is achieved.

- Heating effi ciency of AKKD Type Heating Boilers is 86% and higher.

- Burning air control is made by the digital control unit by enabling velocity and debit control.

- The digital thermostat maintains the system temperature at the adjusted range at the desired temperature.

- The design complies with TSE EN 303-5 standard and has a welded construction according to the European standard EN norm.

- The grids have a special design in order to achieve ideal air-fuel mix. Until 50.000 Kcal/h capacity, high burning effi ciency and cleaning convenience is achieved with the mobile grid system. Burned coal and cinders drop to the ash taking tray easily by means of grid turning and shaking arms and the grids are cleaned and mixing of the fuel with air is achieved. In the models with 60.000 and over, fi xed grids are used and loading of suffi cient amount of coal is enabled and high effi ciency burning is achieved.

- The burning room is designed in dimensions to load suffi cient amount of fuel, and to remove the burned gases easily.

- The coal dumping cap enables impermeability of burned gases and is designed to be easily opened and closed and resistant to deformation. The burning room control can be monitored through the observation window that is resistant to thermic and mechanical shock and burning can be controlled.

- Chimney outlet is achieved from above the chimney fume cupboard until AKKD 100, and from AKKD 120, chimney outlet is achieved from behind of the chimney fume cupboard.

- The coal dumping cap enables impermeability of burned gases and is designed to be easily opened and closed and resistant to deformation. The burning room control can be monitored through the observation window that is resistant to thermic and mechanical shock and burning can be controlled.

- Ash removal cap is present in all models. Burned coal and cinder can be taken from the ash removal chamber easily by the ash removal tray and the boiler cleaning can be made.

- Thanks to the cleaning cap, the heating boiler pipes can be cleaned regularly.

- Their outer body and front caps are designed to be easily dismounted for the convenience of service and assembly.

- Impermeability components used in the heating boiler caps are designed according to human health and environmental conditions protection criteria. The caps are coated with special refractor material.

- Heating boiler has very good heat isolation and it does not give the heat inside to outside. The entire heating boiler is coated with an insulation material.

- The fan enables the required burning air by the digital control unit by controlling the debit and pressure. Fan velocity control keeps the burning effi ciency at a maximum level and it overcomes the gas ways reverse pressure that occurs within the boiler easily.

- The fan valve is mobile and it allows air entry to the burning room during fan working. When the boiler is in sleep mode, air entry to the burning room is prevented and burning control is enabled. The fan valve prevents the entry of burned coal and cinder into the fan body and deformation of the fan leaves.

- The heating boiler temperature is maintained in the desired value range by the digital control system. It can be controlled remotely without cable based on desire.

- Chimney draught is controlled by an adjustable chimney valve.

- In heating boilers within 25.000 kcal/h and 60.000 kcal/h range, a three stage circulation pump is provided.

- The chimney outlet is from the behind in AKKD Model Heating Boilers until 100.000 Kcal/h, and it is from the upper side until 120.000 Kcal/h.

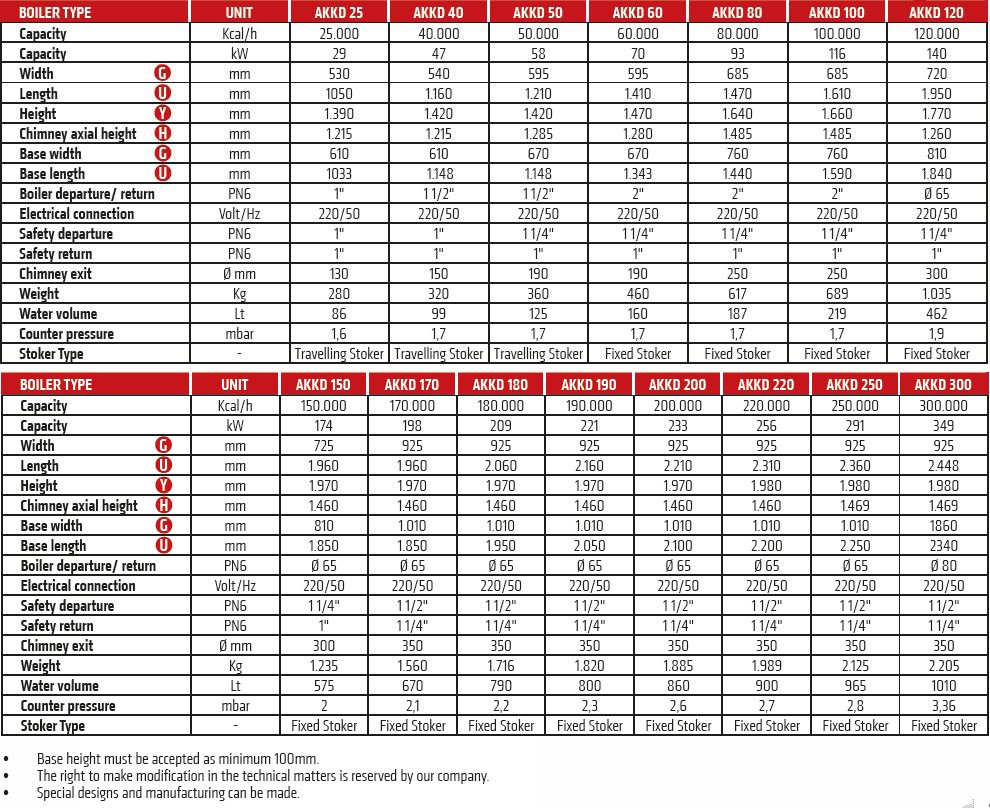

AKKD Solid Fuel Fan Three Transitive Heating Boilers - Technical Dimensions